Comprehensive Underwater Metal Thickness Measurement Services

Ensuring the Integrity and Longevity of Submerged Metallic Structures

The structural integrity of submerged metallic assets is paramount for operational safety, environmental protection, and economic viability. Over time, factors like corrosion, erosion, and wear can degrade metal thickness, potentially leading to catastrophic failures if left unchecked. Our specialized Underwater Metal Thickness Measurement Services provide crucial insights into the condition of these vital assets, enabling proactive maintenance and informed decision-making.

What is Underwater Metal Thickness Measurement?

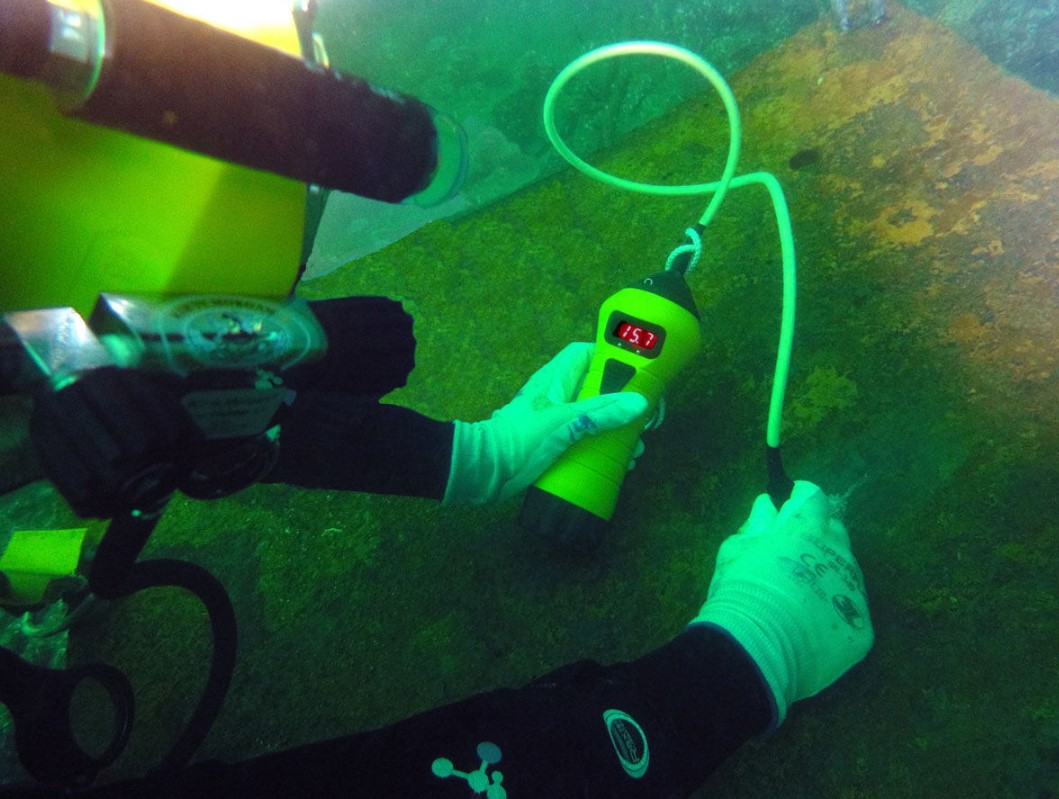

Underwater metal thickness measurement is a non-destructive testing (NDT) technique specifically designed to accurately gauge the thickness of metal structures situated below the waterline. Utilizing advanced ultrasonic technology, specialized probes emit sound waves that travel through the material. By measuring the time it takes for these waves to reflect off the back surface or any internal anomalies and return to the probe, we can precisely calculate the material’s thickness. This process is conducted using remotely operated vehicles (ROVs) equipped with specialized sensors or by highly trained divers employing submersible ultrasonic thickness gauges, ensuring accuracy even in challenging underwater environments.

Why is This Service Critically Important?

Submerged metallic structures, including ship hulls, offshore platform components, pipelines, bridge supports, dam structures, and storage tanks, are constantly exposed to harsh conditions that accelerate degradation.

- Corrosion Monitoring: Seawater, freshwater, and various industrial fluids can cause significant corrosion. Regular thickness measurements identify areas of metal loss, allowing for targeted repairs before structural integrity is compromised.

- Safety Assurance: Thinning metal, especially in critical load-bearing structures or pressurized systems, poses severe safety risks. Accurate measurements ensure assets meet safety standards and can withstand operational stresses.

- Regulatory Compliance: Many industries operate under strict regulations requiring periodic inspections and verification of structural integrity. Our services provide the necessary data to meet and document compliance with maritime, environmental, and industrial standards.

- Predictive Maintenance: By tracking thickness changes over time, organizations can move from reactive repairs to predictive maintenance strategies. This allows for planned interventions, reducing unexpected downtime and maintenance costs.

- Asset Life Extension: Understanding the rate of material degradation enables the implementation of effective corrosion protection systems and timely repairs, significantly extending the operational lifespan of valuable assets.

- Risk Management: Undetected structural weaknesses can lead to costly failures, environmental damage, and reputational harm. Thickness measurements are a fundamental component of a comprehensive risk management strategy.

Applications Across Industries:

Our Underwater Metal Thickness Measurement Services are indispensable for a wide range of sectors:

- Maritime & Shipping: Hull integrity inspections for ships, barges, and floating structures. Classification society survey support.

- Offshore Oil & Gas: Inspection of platform jackets, risers, subsea pipelines, and floating production storage and offloading (FPSO) units.

- Renewable Energy: Monitoring foundations of offshore wind turbines and other marine energy devices.

- Civil Infrastructure: Assessing bridge pilings, dam gates, intake structures, and submerged tunnels.

- Power Generation: Inspecting cooling water intake/outfall structures and submerged components.

- Wastewater Treatment: Evaluating tanks, pipelines, and processing equipment.

The Need for Proactive Assessment: A Message to Organizations

- For Companies: Unforeseen failures of submerged assets lead to costly operational shutdowns, emergency repairs, and potential environmental liabilities. Investing in regular underwater thickness measurements is a proactive step towards ensuring operational continuity, optimizing maintenance budgets through predictive scheduling, and safeguarding your investments. Mitigate risks, enhance efficiency, and protect your bottom line.

- For Governments & Regulatory Bodies: Ensuring public safety and environmental protection requires diligent oversight of critical infrastructure, much of which lies underwater. Our services provide verifiable data to assess the condition of public assets like bridges, dams, and port facilities, supporting regulatory compliance, informing infrastructure spending priorities, and upholding safety mandates. Ensure the long-term viability and safety of essential public works.

- For Institutions & Asset Managers: Managing large portfolios of submerged or partially submerged infrastructure demands accurate condition assessments for effective long-term planning and resource allocation. Underwater thickness measurements provide the crucial data needed for life-cycle analysis, prioritizing maintenance efforts, validating insurance assessments, and ensuring the longevity and reliability of managed assets. Make informed decisions based on precise, objective data.

Our Commitment to Excellence:

We employ state-of-the-art ultrasonic equipment and adhere to rigorous industry standards to deliver highly accurate and reliable thickness measurements. Our experienced technicians and advanced deployment methods (including ROVs for inaccessible or hazardous areas) ensure comprehensive inspections tailored to your specific needs. Detailed reporting provides clear, actionable data for your maintenance and integrity management programs.

Ensure the safety, compliance, and longevity of your underwater metallic assets. Contact us to learn how our specialized thickness measurement services can benefit your operations.