Advanced Underwater Thickness Measurement for Non-Metallic Materials

Safeguarding the Integrity of Submerged Fiberglass, Polypropylene, PVC, PET, and Polyethylene Assets

The use of advanced non-metallic materials like Fiberglass (GRP/FRP), Polypropylene (PP), Polyvinyl Chloride (PVC), Polyethylene Terephthalate (PET), and Polyethylene (PE) in submerged applications is rapidly growing due to their corrosion resistance, weight advantages, and versatility. However, these materials are not immune to degradation and damage over time when exposed to underwater environments. Our specialized Underwater Thickness Measurement Services for non-metallic materials provide essential data to monitor their condition, ensuring operational safety, environmental compliance, and asset longevity.

What is Underwater Non-Metallic Thickness Measurement?

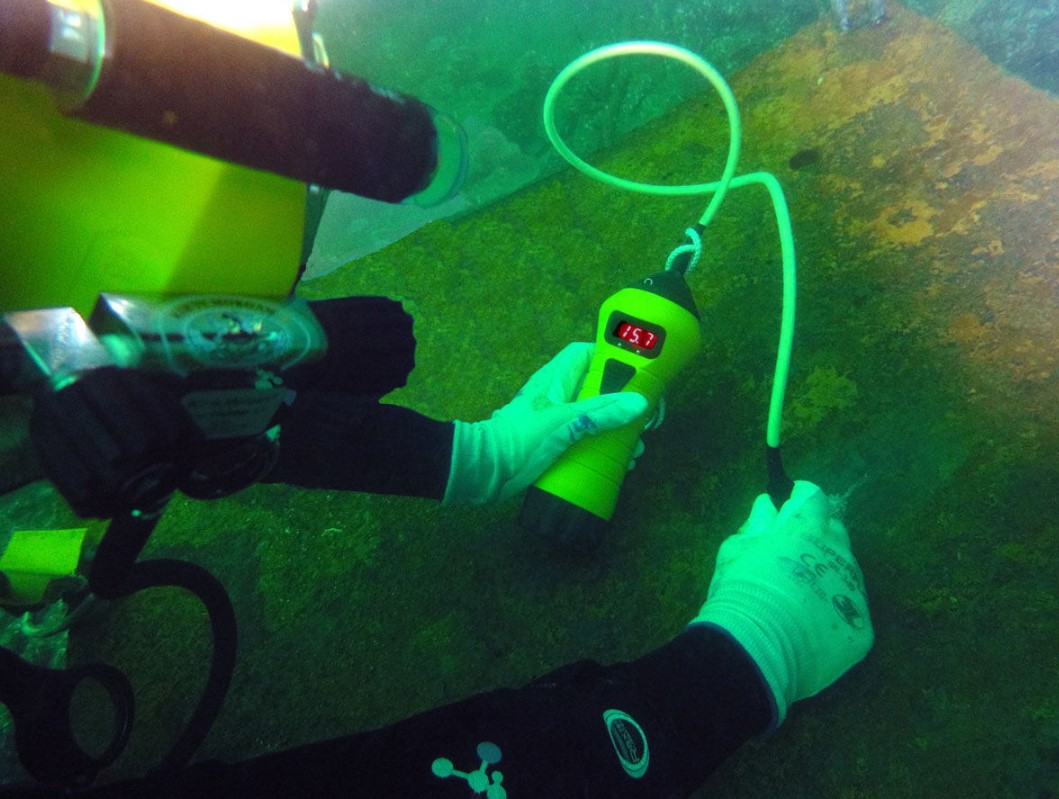

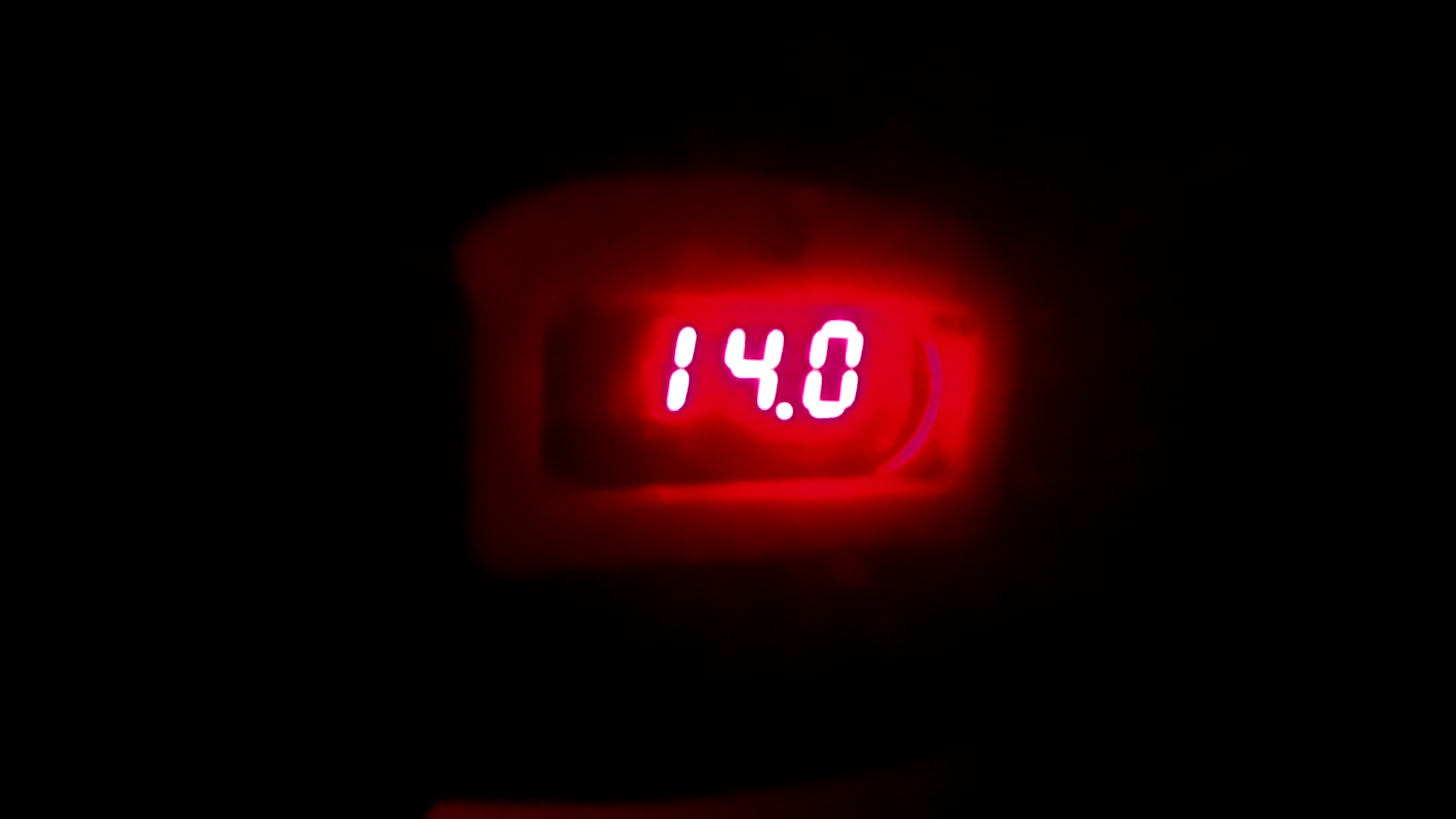

This service involves specialized non-destructive testing (NDT) techniques adapted to accurately measure the thickness of various polymers and composite materials situated below the waterline. While advanced ultrasonic testing (UT) remains a primary method, its application to non-metallics requires specific expertise, specialized equipment, and careful calibration due to the unique acoustic properties of these materials (which differ significantly from metals). Sound waves travel differently through polymers and composites, and factors like material density, elasticity, potential layering (in fiberglass), and surface condition must be accounted for. Depending on the specific material and application, alternative or complementary NDT methods might also be employed to ensure the highest accuracy. Measurements are typically performed using remotely operated vehicles (ROVs) or skilled divers equipped with specifically calibrated sensors.

Why is Measuring Non-Metallic Thickness Crucial?

Despite their resistance to traditional corrosion, polymers and composites face their own set of challenges in submerged environments:1

- Material Degradation: These materials can degrade through various mechanisms:

- Fiberglass (GRP/FRP): Osmotic blistering (water ingress separating layers), hydrolysis (chemical breakdown of resin by water), impact damage, and abrasion.

- PP, PVC, PE, PET: Chemical attack from specific substances, UV degradation (especially near the waterline or if exposed prior to submersion), environmental stress cracking, abrasion, impact damage, and material creep under load.

- Structural Integrity Assessment: Thinning or damage can compromise the load-bearing capacity of tanks, pipes, boat hulls, pontoons, and other structures, potentially leading to leaks or structural failure.

- Containment Assurance: For pipes (PVC, PE, PP) and tanks (GRP, PE, PP) used for water, wastewater, or chemical transport/storage, maintaining wall thickness is critical to prevent leaks and ensure environmental protection.

- Quality Control & Compliance: Verifying the thickness of liners (e.g., PE, PVC in tanks or ponds) or newly installed components against design specifications is essential for quality assurance and regulatory compliance.

- Wear and Tear Monitoring: Abrasion from water flow, sediments, or mechanical contact can reduce material thickness over time, particularly in pipes and dynamic structures like aquaculture cages (PE).

- Informed Maintenance & Lifespan Management: Understanding the condition and rate of degradation allows for planned maintenance, targeted repairs (e.g., patching GRP, welding compatible thermoplastics), and realistic estimations of remaining service life.

Applications Across Diverse Sectors:

Our expertise covers a wide range of applications involving submerged non-metallic materials:

- Maritime: Fiberglass (GRP) vessel hulls, pontoons, sonar domes, non-metallic tanks, and buoys.

- Aquaculture: High-Density Polyethylene (HDPE) fish farm cages, tanks, and piping systems.

- Water & Wastewater Management: PVC, PE, and PP pipelines; GRP tanks and containment vessels; PE and PVC liners for ponds and reservoirs.

- Chemical Processing & Storage: Corrosion-resistant PP, PVC, and GRP tanks, pipes, and liners handling specific chemicals.

- Civil Infrastructure: GRP structural components, composite reinforcements, pipe rehabilitation liners (often PET-based CIPP), PE culverts.

- Recreational Facilities: PVC pool liners, PE floating dock components.

The Imperative for Specialized Inspection: A Message to Organizations

- For Companies: Failures in non-metallic assets like GRP boat hulls, chemical storage tanks (PP, GRP), or aquaculture infrastructure (PE) can lead to significant financial losses, environmental incidents, and operational halts. Standard metal inspection techniques may not suffice. Our specialized service provides accurate condition assessments for these critical materials, mitigating risks associated with leaks, structural failures, and chemical incompatibility. Ensure the reliability and safety of your diverse material assets.

- For Governments & Public Utilities: Municipal water/wastewater networks increasingly rely on PVC and PE pipes, while GRP is used in treatment plants and infrastructure. Ensuring the integrity of these systems is vital for public health and environmental safety. Our non-metallic thickness measurement services offer the data needed to monitor these assets effectively, comply with regulations, prevent costly failures, and plan for long-term infrastructure maintenance and rehabilitation. Uphold public trust and environmental standards.

- For Institutions & Asset Managers: Overseeing facilities or infrastructure often involves a mix of metallic and non-metallic components. Degradation modes differ significantly. Relying solely on metal-focused inspections leaves potential vulnerabilities unaddressed. Our service provides the specialized capability to assess the condition of submerged Fiberglass, PP, PVC, PET, and PE assets, enabling comprehensive risk management, optimized maintenance scheduling across your entire portfolio, and maximizing asset lifespan. Gain a complete picture of your asset health.

Leveraging Expertise and Technology:

We utilize advanced NDT equipment specifically chosen and calibrated for the challenges of measuring thickness in various polymers and composites underwater. Our technicians possess the specialized knowledge required to interpret results accurately, considering material type and environmental factors. Whether using ROVs for safe remote access or deploying expert divers, we deliver precise, actionable data through comprehensive reporting, empowering you to manage your non-metallic assets effectively.

Protect your investment and ensure the continued safe operation of your submerged non-metallic structures. Reach out to discover how our specialized thickness measurement services can address your specific needs.