Diving into the depths of the ocean can be an exciting and dangerous endeavor, especially when inspecting the walls and tubes of underwater structures. Divers must be equipped with the right tools to ensure their safety and the accuracy of their inspection. Ultrasonic underwater thickness gauges are one such tool that has proven to be indispensable for divers inspecting underwater tubes and walls. In this article, we will explore how ultrasonic underwater thickness gauges help divers inspect tubes and walls and provide a few laughs along the way.

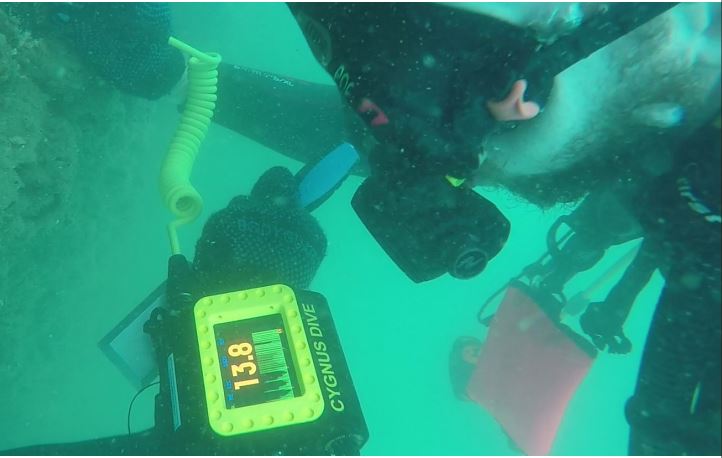

Ultrasonic underwater thickness gauges work by emitting high-frequency sound waves through the walls or tubes of underwater structures. The sound waves bounce back to the gauge and are then used to measure the thickness of the wall or tube. This information is critical for divers inspecting underwater structures, as it can identify any areas that may be at risk of corrosion or other forms of damage.

One of the benefits of using an ultrasonic underwater thickness gauge is that it allows divers to inspect underwater structures without damaging them. Unlike other forms of inspection, such as cutting or drilling, ultrasonic inspection is non-destructive. This means that divers can quickly and accurately identify potential issues without causing any harm to the structure or surrounding environment.

Another advantage of using ultrasonic underwater thickness gauges is their portability. These gauges are small and lightweight, making them easy to carry with you underwater. Divers can quickly move from one area to another and take readings as needed. Additionally, some gauges are designed to work in low-light conditions, which can be helpful when inspecting structures that are not well-lit.

While ultrasonic underwater thickness gauges are incredibly useful, they do require some skill to use effectively. Divers must be trained to operate the gauge correctly and interpret the readings accurately. They must also take into account factors such as water temperature, pressure, and salinity, which can affect the accuracy of the readings. For this reason, it is crucial that divers receive proper training and certification before using ultrasonic underwater thickness gauges.

In conclusion, ultrasonic underwater thickness gauges are an essential tool for divers inspecting underwater tubes and walls. They provide accurate, non-destructive measurements of the thickness of underwater structures, allowing divers to identify potential issues quickly. While they require some training and skill to use effectively, their portability and non-destructive nature make them an invaluable asset to any diver’s toolkit.

References:

- “Ultrasonic Thickness Gauges for Diving and Underwater Inspection” by Cygnus Instruments Ltd.

- “Ultrasonic Thickness Gauges for Non-Destructive Testing” by Olympus Corporation.

- “Underwater Inspection: What You Need to Know” by International Diving Institute.

Humor:

Why did the ultrasonic underwater thickness gauge refuse to dive? Because it was afraid of getting wet! But in all seriousness, while these gauges may be a little hesitant about diving, they are incredibly useful for divers inspecting underwater structures. So let’s give a round of applause for our trusty ultrasonic underwater thickness gauges, who help us keep our underwater structures safe and sound.